BE SMART.

BE PRODUCTIVE.

BE SCHUR.

Leaders in Pump Manufacturing

Get Immediate Assistance With Your Pumps... Always!

Speak With An Expert

I agree to terms & conditions provided by the company. By providing my phone number, I agree to receive text messages from the business.

- Global Pump Manufacturers

Schurco maintains a global network of distribution and guarantees quality assurance

- Compatible With Warman® Parts

We offer spare parts compatible with other pump manufacturers like Warman® Slurry Pumps.

- Engineered to Perfection

Our pumps are built to last, resistant to wear and tear and are dependable.

Speak With An Expert

I agree to terms & conditions provided by the company. By providing my phone number, I agree to receive text messages from the business.

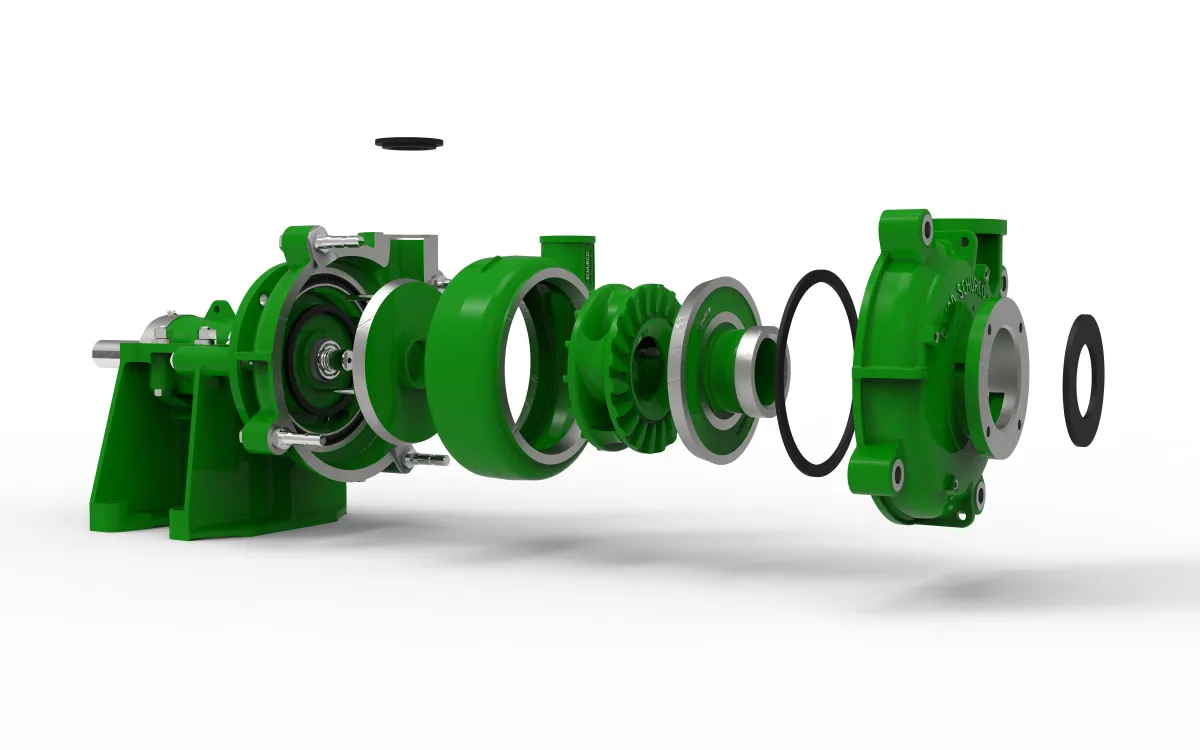

SLURRY PUMP MANUFACTURER

DELIVERING QUALITY, AVAILABILITY, TECHNICAL EXPERTISE AND VALUE

Schurco Slurry manufactures high-quality heavy-duty horizontal slurry pumps, vertical slurry pumps, replacement pump parts, and provides pump services to a wide array of markets worldwide.

Schurco Slurry pumps and replacement parts are the go-to sources for heavy-duty centrifugal slurry pumps in industries like hard rock mining, mineral processing, power generation, aggregate production, or any type of slurry pumping application. Schurco specializes in handling the toughest and most abrasive applications, while supplying new slurry pumps with some of the lowest lead times in the industry.

With low lead times and attentive customer service, Schurco Slurry is one of the few remaining American ultra-heavy-duty slurry pump manufacturers delivering unmatched quality, engineering expertise and product value. Schurco is a recognized leader in slurry pump manufacturing, pump repairs, pump remanufacturing and quality replacement parts.

You can feel confident buying from Schurco Slurry with the quality and service expectations that come with purchasing from an American manufacturer.

Slurry Pumps

All Of Our Services!

Spare Parts

The very nature of pumping solids means that destructive wear on internal parts is an inevitable part of the life cycle of your slurry pumps.

Managing and reducing that wear is what Schurco Slurry® does for our customers.

Schurco Slurry® manufactures quality metal and elastomer replacement parts fully compatible with pumps, and provides value to customers through fair pricing and lead times that are some of the lowest in the market. We stock millions of dollars of pumps and parts globally, all of which are interchangeable with slurry pump parts. We maintain a global distribution network that stands ready to serve your process needs.

All parts compatible with the slurry pumps have been rigorously reverse engineered using FaroArm® technology with 2D 3-D modeling. First article inspection involves comparison to OEM parts followed by fit testing. All impellers have been performance tested to certify them against OEM performance. Schurco Slurry manufactures replacement parts for other manufacturers as we do our own: with technical expertise, quality, fair pricing, and product availability for the end user.

Pump Repair

We offer complete refurbishing programs for Schurco Slurry and other pumps due for repair.

Once the pump is received and inventoried by our team of experienced mechanics and machinists, we identify and report on which parts can and will be salvaged and which must be replaced. Providing options, customers will be quoted the cost of repair on the original pump, and the cost of a new Schurco Slurry® replacement pump.

This is a desirable alternative for many customers considering the high cost and lead times that exist in heavy industry today. Our extensive stock of replacement parts and pumps provide options to our customers that are both cost effective and reduce downtime.

Bearing Assembly Exchange/Repair Programs

We know that aside from replacing worn wet end parts, bearing assembly repairs are extremely important in the pumping industry.

As such, we have options for bearing assembly exchange/repair programs that can keep you up and running while we work on your assembly. We only use the highest quality bearings from manufacturers such as Timken, SKF, NSK, or FAG.